Types Of Fouling In Heat Exchangers

What is fouling in Heat Exchangers?

Fouling is the accumulation

of unwanted material on the tube surfaces of the heat exchanger. After a period

of operation the heat transfer surface of heat exchanger may become coated with

various deposits presents in flow system. This coating represents an additional

resistance to heat flow and thus decreased in performance. Fouling factors are

best determined from experience with similar units in the same or similar

service. When such information is not available, recourse may be had to publish

data. The most comprehensive tabulation of fouling factors is the one developed

by TEMA, which is available in Refs. [1, 2]. Fouling can occur by a number of

mechanisms operating either alone or in combination. These include:

- Corrosion:

Corrosion products

such as rust can gradually build up on tube walls, resulting in reduced heat

transmission and eventual tube failure. This type of fouling can be minimized

or eliminated by the proper choice of corrosion-resistant materials of

construction in the design process.

- Crystallization:

- Decomposition:

Some organic

compounds may decompose when they are heated or come in contact with a hot

surface, forming carbonaceous deposits such as coke and tar. In cracking

furnaces, partial decomposition of the hydrocarbon feedstock is the objective

and coke formation is an undesired but unavoidable result.

- Polymerization:

- Sedimentation:

Sedimentation fouling results from the

deposition of suspended solids entrained in many process streams such as

cooling water and flue gases. High fluid velocities tend to minimize the

accumulation of deposits on heat-transfer surfaces.

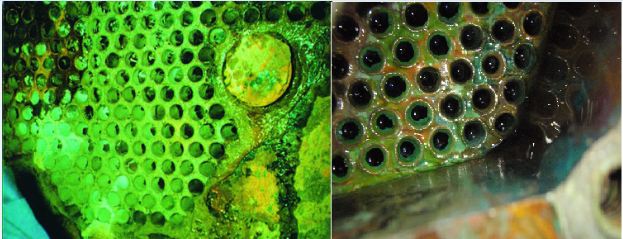

- Biological activity:

Biological fouling is

most commonly caused by micro-organisms, although macroscopic marine organisms

can sometimes cause problems as well. Cooling water and some other process

streams may contain algae or bacteria that can attach and grow on heat-transfer

surfaces, forming slimes that are very poor heat conductors. Metabolic products

of these organisms can also cause corrosion of metal surfaces. Biocides and

copper-nickel alloy tubing can be used to inhibit the growth of micro-organisms

and mitigate this type of fouling.

References:

- Kakac, S. and H. Lui, Heat Exchangers: Selection, Rating and Thermal Design, CRC Press Boca Raton FL, 1997.

- Standards of the Tubular Exchanger Manufacturers Association, 8th edn, Tubular Exchanger Manufacturers Assiociation, Inc, Tarrytown, NY, 1999.

I really like the heater project. It gives me ideas beyond my imaginations. Heating and Cooling Oakville

ReplyDeleteThis is a nice post. It has a good tips here. Thank you for sharing. For more information visit here https://aicheatexchangers.com/

ReplyDelete

ReplyDeleteNice article. Thanks for sharing this nice information for me. I hope you will share some more information.We also offer heat exchanger .

Nice blog. Thanks for sharing a nice blog. It’s very interesting and useful for me....please visit my website I assure you that it will benefit you." air to air heat exchanger"

ReplyDeleteAir cooled heat exchangers are used to transfer heat from a process fluid to ambient air. The process fluid is contained within heat conducting tubes.

ReplyDeleteI really enjoyed this post. You describe this topic very well. I really enjoy reading your blog and I will definitely bookmark it! Keep up the interesting posts! Thanks for sharing informative blog. Visit here: “ Heat Exchanger Manufacturers”

ReplyDeleteHere we come up with new machinery plant named Alaquainc, which specializes in designing and manufacturing a broad range of different crystallizer systems designs to fulfill diverse client requirements. To learn more about Alaqua Inc please visit on the website www.alaquainc.com

ReplyDeleteThanks for sharing very informative data about types of fouling in heat exchangers.

ReplyDeletecan you please note and share the best Shell and tube oil cooler manufacturersand share it.

ReplyDeleteAlaquainc, which specializes in designing and manufacturing a broad range of different crystallizer systems designs to fulfill diverse client requirements.

ReplyDeleteThanks For Shareing This you blog is Really very nice in this blog I relly like this topic.made in usa distillation equipment A cracked heat exchanger should never be attempted to be inspected and/or repaired by the homeowner. and should instead be replaced. Request an inspection and diagnosis from a trained technician. An expert can tell you on the best option and how to maintain your heating system.

ReplyDeleteNice articles and your information valuable and good articles thank for the sharing information Industrial heat exchangers

ReplyDeleteSwastik Hydraulic is a leading manufacturer of high-quality shell and tube heat exchangers. We are trusted Shell and Tube Heat Exchanger Manufacturers in New Delhi, known for our precision and performance. Our expertise also extends as reliable Shell and Tube Heat Exchanger Manufacturers in Noida and Shell and Tube Heat Exchanger Manufacturers in Ahmedabad, serving various industries with efficient thermal solutions.

ReplyDeleteI simply loved this post. You describe this topics very well. I without a doubt enjoy analyzing your blog and I will really bookmark it! Keep up the interesting posts! Thanks for sharing informative blog. Anpam Engineering is a leading manufacturer of heat exchangers in India, considered for its high quality goods and innovative technology. Visit here: Heat Exchanger Manufacturer , Heat exchanger design

ReplyDeleteThanks for sharing such an informative post! I was recently looking into different cooling systems for industrial equipment, and I found that aircooledoilcoolers offer excellent efficiency, lower maintenance needs, and improved equipment performance. Your explanation made the concept much clearer and highlighted their real-world benefits. Looking forward to reading more of your insightful articles.

ReplyDeleteThank you for the helpful blog, "Types Of Fouling In Heat Exchangers." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes