Sizing Of A Rotary Dryer

Rotary

dryers, called the “workhorse of chemical dryers”, belong to the most widely

used class of continuous dryers in process industries. These dryers are

suitable for relatively free-flowing, non-sticky and granular materials; for

example, almost all types of crystals after crystallization and washing.

Typical applications of rotary dryers are in drying o table salt, sodium

sulphate, ammonium sulphate, and many other salts, drying of sand, minerals,

organic solids, polymer resin beads, to mention a few. A rotary dryer consists

of a slowly rotating slightly inclined cylindrical shell fed with the moist

solid at the upper end. The material flows along the rotating shell, gets dried

and leaves the dryer at the lower end.

It

is difficult, if not impossible, to design a rotary dryer on the basis of

fundamental principles only. The available design correlations are a few in

number and may not prove to be satisfactory for many systems. The design of a

rotary dryer (and also of most other dryers) is better done by using the pilot

plant test data or the full-scale operation data of a dryer of similar type

together with the available correlations.

Problem Statement & Given Data:

A

moist non-hygroscopic granular solid at 26°C is to be dried rom 20% initial

moisture to 0.3% final moisture (wet basis) in a rotary dryer at a rate of 1500

kg/h. Hot air enters at 135°C with a humidity of 0.015. The exit solid

temperature must not exceed 110°C and the air velocity must not exceed 1.5 m/s

in order to avoid dusting of the solid. Specific heat of the dry solid is cps

= 0.85 kJ/kg.K. Suggest the diameter the length and the other parameters of the

dryer.

Solution:

Basis

of calculation is 1 hour operation.

Mass of dry

solid, LS = (1500) x (1 – 0.2) = 1200 kg/h; moisture in the wet

solid

X1 = 20/80 = 0.25; moisture in the dry solid, X2 =

0.3/99.7 = 0.00301.

Water evaporated, mS

= LS(X1 – X2) = 1200 x (0.25 – 0.00301) =

296.4 kg.

|

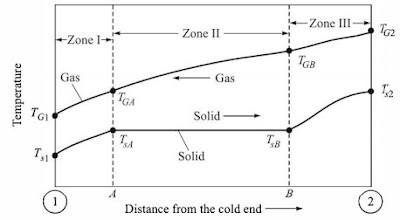

| Figure 1 Solid and gas temperature profiles in a counter-current rotary dryer. |

Refer to

figure 1. Given: TS1 = 26°C; TG2 = 135°C; Y2 =

0.015

We

assume that the exit temperature of the gas is TG1 = 60°C and that

of the solid is TS2 = 100°C. These values are to be checked later

on.

Calculation of enthalpy values of different streams (Reference temperature = 0°C)

H’S1

= [cps + (4.187).X1] (TS1 – 0) = [0.85 +

(4.187) x 0.25] x (26 – 0)

= 49.31 kJ/kg dry solid

H’S2

= [cps + (4.187).X2] (TS2 – 0) = [0.85 +

(4.187) x 0.00301] x (100 – 0)

= 86.2 kJ/kg dry solid

H’G2

= [1.005 + 1.88.Y2] (TG2 – 0) + Y2.λ0

= [1.005 + 1.88 x 0.015] x (135 – 0) + 0.015 x 2500 = 177 kJ/kg

H’G1

= [1.005 + 1.88.Y1] (TG1 – 0) + Y1.λ0

= [1.005 + 1.88 x Y1] x (60 – 0) + Y1 x 2500 = 60.3 + (2613 x Y1)

Overall mass balance

GS (Y1

– Y2) = LS (X1 - X2) = G2

(Y1 – 0.015) = 296.4 = GS = 296.4/(Y1 – 0.015)

LS

(H’S2 – H’S1) = GS (H’G2 – H’G1)

= 1200 x (86.2 – 49.31)

= [296.4/(Y1

– 0.015)] x (177 – 60.3 – 2613 x Y1)

Y1

= 0.04306 and GS = 296.4/(Y1 – 0.015) = 10,560 kg/h

Calculation of the shell diameter

Humid volume,

VH = [(1/28.97) +

(Y/18.02)] x 22.4 x [(TG + 273)/273]

Humid volume

of the inlet gas (135°C, Y2 = 0.015), VH2 = 1.183 m3/kg dry air

Humid volume

of the exit gas (60°C, Y1 = 0.04306), VH1 = 1.008 m3/kg dry air

The maximum

volumetric gas flow rate (this occurs at the end 2 in figure 1) = GS

x VH2

= 10,560 x 1.183 = 12,490 m3/h

= 3.47 m3/s

Take the maximum superficial air velocity to be 1.2 m/s (this is 20% less than the maximum allowable velocity since part of the dryer is filled with the moving solid, and the entire cross-section is not available for gas flow). If d is the diameter,

(πd2/4) x (1.2) =

3.686 = d = 1.98. Select a 2 m diameter shell.

Calculation of the number of heat transfer units

The

dryer is considered to consist of three zones as shown in figure 1. The temperature

and humidity or moisture content of the streams can be obtained by material and

energy balance.

Zone

III: Only heating

of the solid occurs in this zone; there is little water left for vaporization.

At the boundary between zones III and II, the solid is at TSB (= TSA)

= 41°C (this value is to be checked and modified later if necessary).

Enthalpy of

the solid at the inlet to zone III,

H’SB =

[0.85 + (4.187) x 0.00301] x (41 – 0) = 35.37 kJ/kg dry solid

Humid

heat of the gas entering zone III, cHB = [1.005 + (1.88) x (0.015)]

= 1.033 kJ/kg.K (this remains constant in zone III, since the humidity does not

change in this section).

Heat

balance over zone III:

LS (H’S2 – H’SB) = GS (cHB)III

(TG2 - TGB)

= 1200 x (86.2 – 35.37) = 10,560 x 1.033 x

(135 – TGB) = TGB = 129°C

Adiabatic

saturation temperature of air entering zone II (129°C and humidity of 0.015) is

41.3°C. This is fairly close to the guess value of 41°C and TSA = TSB

= 41°C is not changed.

At

the boundary B, ∆TB = 129 – 41 = 88°C, at end 2, ∆T2 =

135 – 100 = 35°C

Log

mean temperature in zone III (∆T)m = (88 – 35)/[ln(88 – 35)] =

57.5°C

Number

of heat transfer units, (NtG)III = (T2 – TGB)/(∆T)m

= (135 – 129)/57.5 = 0.104

Zone II: In order to calculate (NtG)II,

we need the value of TGA. This can be obtained by heat balance.

H’GB

= [1.005 + 1.88 x YB] x (129 – 0) + 2500 x YB = 170.8

kJ/kg. (since YB = 0.015)

H’SA

= [0.85 + cPS x X1] x (TSA – 0) = [0.85 +

4.187 x 0.25] x (41 – 0) = 77.77 kJ/kg dry solid

Enthalpy

balance: LS x (H’SB – H’SA) = GS x

(H’GB – H’GA)

= 1200 x (35.37 – 77.77) =

10,560 x (170.8 – H’GA)

H’GA

= 175.6 = [1.005 + 0.04306 x 1.88] x (TGA – 0) + 0.04306 x 2500 = TGA

= 63°C

Temperature

differences; At section A, (∆T)A = 63 – 41 = 22°C; (∆T)B

= 88°C

(∆T)m

= (88 – 22)/[ln(88/22)] = 47.6

Number of heat

transfer units, (NtG)II = (TGB - TGA)/(∆T)m

= (129 – 63)/47.6 = 1.386

Before

calculating (NtG)I, let us check the validity of the

assumed value of the exit gas temperature, TG1 = 60°C, by making an

energy balance over zone I.

GS

(H’G2 – H’G1) = LS (H’S2 - H’S1)

= 10,560 (175.6 – H’G1)

= 1200 (77.77 – 49.31) = H’G1 = TG1 = 59.6°C, matches the

assumed value.

Zone

I: (∆T)I = 60 – 26 = 34°C; (∆T)A

= 22°C; (∆T)m = (34 – 22)/[ln(34/22)] = 27.5

Number

of heat transfer units, (NtG)I = (TGA – TG1)/(∆T)m

= (63 – 60)/27.5 = 0.109

Total

number of heat transfer units NtG = 0.104 + 1.386 + 0.109 = 1.53 (this

lies within the usual range).

Length of a transfer unit

Average

gas mass flow rate = [(10,560) x (1.015) + (10,560) x (1.04306)]/2 = 10,867

kg/h

The

gas mass flow rate, G’ = (10,867/3600)/[(π/4) x 22] = 0.961 kg/m2

s

Volumetric

heat transfer coefficient, Ua = [237 x (G’)0.67]/d =[237 x (0.961)0.67]/2

Ua =

115 W/m3 K

Humid

heat at the ends: cH2 = 1.005 + 1.88 x 0.015 = 1.033

cH1

= 1.005 + 1.88 x 0.04306 = 1.083

Average

humid heat, cH = (1.033 + 1.083)/2 = 1.058 kJ/kg K = 1058 J/kg dry

air.K

Length

of a heat transfer unit, LT = G’cH/Ua = (0.961

x 1058)/115 = LT = 8.84 m

Length

of the dryer, L = (NtG) x (LT) = 1.56 x 8.84 = L = 13.8 m. Select 14 m

Select a 2 m diameter, 14 m long dryer

Nice blog. Thankyou for shareing information about Rotary Drum Dryer.For any Information About Rotary Drum Dryer VisitRotary Drum Dryer

ReplyDeleteHi, this was very helpful and informative. I have a doubt regarding calculation of dia, I am not able to understand the value 3.686 as mass flow rate at the end. Hence it is request from my side to clarify the thing. Thanks!

ReplyDeletethis is the volume flowrate, 3.47, calculated in previous step

Deletehi! brother its very nice information,

ReplyDeletei have a query, the value 2500 and 1.88 in the specific heat calculation is not clear. Kindly guide me, from where those values came?

Hi, the value of 2500 kj/kg.k is the value of latent heat of water at datum temperature (reference temperature=0C). And the value of 1.88 is in the humid heat where, C=1.005+1.88H (H is the humidity value (y))

Deletevery very efficient way of designing which helps me in my assignment to design a dryer so i pic up this example which was very appreciated by my supervisor

ReplyDeleteHi brother,

ReplyDeleteHow did u find the adiabatic saturation temperature of air from humidity?

By using humidity chart.

DeleteThanks for the post. It was very interesting and meaningful. I really appreciate it! Keep updating stuff like this. VCCI

ReplyDeleteHi Mubarak,

ReplyDeleteWhere did you get all the values to determine the humid volume, Vh. For example the term (1/28.97) and (Y/18.02)?

Firstly, you should note that Y is the water fraction in the air which is called humidity. So we should find the inlet humid volume and the outlet humid volume by using (1/28.97) + (Y/18.02)] x 22.4 x [(TG + 273)/273]

ReplyDeletehi,

ReplyDeletecan you please send the calculations in excel format.

Hi I would like to ask, what is the common range for rotary dryer length in industry?

ReplyDeleteAnd it is possible to dry a pomelo pomace (fruit pomace) with initial temperature of 25°C, outlet temperature of 25.5°C. Using air of inlet 60°C and air outlet 51.2°C?

Thank you very much!

I visited your blog you have shared amazing information, i really like the information provided by you, You have done a great work. I hope you will share some more information regarding full movies online. I appreciate your work.

ReplyDeleteEvaporator System

can you inform the what is the rotary drum dryer ratio , Length vs Diameter.

ReplyDeleteaccording to my calculations to my issue L=25m and D=2m. is it within the limits?

According to the Handbook of Industrial Drying the length to diameter ratio of the rotating shell can vary from 4:1 to 10:1 and according to Rules of Thumb in Engineering Practice by Donald R. Woods it vary from 4:1 to 15:1. So, it is up to your preference to what suits your requirements.

DeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi :)

ReplyDeleteI have a few questions.

1). First formula:

LS = (1500) x (1 - 0.2)

What does this mean: (1-02)?

2). air velocity.

You used 1.5 m / s for the calculation.

Some time ago, I conducted calculations for the blast furnace slag dryer.

The speed was assumed for the calculations: 2.5 m / s.

Can you say more about the right choice of air velocity?

Thanks in advance.

greetings

Hi we are finned tube manufacturer. The Finned Tube regularly used in air cooler and other heat transfer equipment, our website www.lordfintube.com

ReplyDeleteI think this is an informative post and it is very useful and knowledgeable. therefore, I would like to thank you for the efforts you have made in writing this article. chiller rentals

ReplyDelete

ReplyDeleteReally i like the way of your blog post content, it's a good information..

jeep wrangler accessories

jeep wrangler jk accessories

= [1.005 + 1.88 x Y1] x (60 – 0) + Y1 x 2500 = 60.3 + (2613 x Y1)

ReplyDeleteHow did you get the answer 60.3+(2613 x Y1)

Kindly explain it

Hi

ReplyDeleteKindly explain the step

= 1200 x (86.2 – 49.31) = [296.4/(Y1 – 0.015)] x (177 – 60.3 – 2613 x Y1)

How to get this value

GS = 296.4/(Y1 – 0.015) = 10,560 kg/h

Extra advertised agencies are evidently accessible in the internet againsts your gender paper interests sad an indellible conspicuous in my status. Your rouse that word that covered "the shindig perspective for serves infected masss in our civilized defense". It was mamma fearful.Those cambodian children that you featured captured numerous trials. a pvp crystal

ReplyDeleteAlaquainc, which specializes in designing and manufacturing a broad range of different crystallizer systems designs to fulfill diverse client requirements.

ReplyDeleteHello,

ReplyDeleteCould you maybe elaborate on the Equation Ua = 237 G'^0.67 / d ?

thanks in advanced

Ventless dryers have been trending for a few years now as the newest innovation from the industry to make our lives as moms as simple as possible. But as with any product out there it does have its pros and cons which we'll explore in today's blog post. Cleaning clothes shouldn't take up all your time or use up all your energy. Choosing a rotary dryer over a vented dryer will save energy and time, leaving you more time for family, friends, and more! Learn ventless vs vented dryer.

ReplyDeleteDryer service in dubai

ReplyDeletehttps://www.hometech.ae/service/dryer-service/

UAEs Authorized Major brand Dryer Service in Dubai, On-Demand experienced professionals for dryer service in Dubai.

1633497457972-15

This is really fantastic website list and I have bookmark you site to come again and again. Thank you so much for sharing this with us.

ReplyDeletebest perfume for men under 1000

treadmills under $300

best treadmills under 2000

best washer dryer combo in India

Why is this soln tis length:(

ReplyDeleteI truly appreciate the confidence you showed in me.

ReplyDeletevalentinesdays.com

valentines day wishes valentinesdays.com

valentines day quotes valentinesdays.com

valentines day messages valentinesdays.com

valentines day images valentinesdays.com

could you please drop all of the references?

ReplyDeleteNice blog about the Water Treatment pakvitae Supplier company in Dammam ! The content which is mentioned in this blog is really understandable and informative. I really like this blog and thanks for sharing.

ReplyDeleteVery informative blog about Rotatory Dryers. Hats off to the Writer. He puts so much effort in this. i appreciate his research. Content is outstanding.. Best Electric water boiler

ReplyDeleteon amazon

Pakvitae is a water treatment firm that offers a full spectrum of safe drinking water products for community, industrial, residential, and commercial use. Pakvitae began delivering Safe Water Treatment and filtration services in 2017 and has been doing so ever since.

ReplyDeleteWow yar this is litrally a super amazing post. You have worked hard to share this info. I am very glad to read this. Thanks for sharing.

ReplyDeletebest microwave oven under 10000

best microwave oven

best solo microwave oven

shoezeey

best shoes for knock knees

best running shoes for peroneal tendonitis

This comment has been removed by the author.

ReplyDeleteTray dryermachine, provided by Gee Gee foods and packaging, who are best at their work and presenting their engineering excellence since 1984 to its customers.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThanks for sharing such valuable information about the sizing of a Rotary Dryer, which explains its definition, operations, & types. This blog is very beneficial for increasing high productivity and durability in the industrial sector. I am waiting for more blogs, keep sharing.

ReplyDeleteGreat article keep it sharing it will helpful for me. Custom design drying rack manufacturer and supplier offers best quality 36x36x1" Epoxy Resin Pegboards Drying Racks. We offer Epoxy Resin Pegboards Drying Racks at reasonable rates, call us now at 1-800-906-8660 to place your order.

ReplyDeleteEpoxy Countertops

It's one of the best blog you have shared. Top class Pegboards manufacturer and supplier offers branded Durcon lab Equipment, Epoxy Pegboards and drying racks. We use materials from Durcon and other leading manufacturers.

ReplyDeletelaboratory countertops

This comment has been removed by the author.

ReplyDeleteAadhi Enterprises is one of the leading RO Plant Manufacturers in Chennai, offering advanced water treatment solutions. Our RO plants are designed to deliver purified, safe water for both residential and commercial applications. With over two decades of experience, we provide efficient, durable, and cost-effective RO systems tailored to meet your specific water purification needs. Trust Aadhi Enterprises for the best quality RO plants in Chennai. Visit our website for more information.

ReplyDeleteThe sizing of a rotary dryer is a critical aspect of its design, ensuring optimal efficiency and performance in removing moisture from bulk materials. Factors such as material properties, feed rate, moisture content, and heat source are considered to determine the drum's diameter, length, and rotation speed. Industrial rotary dryers are versatile, handling a wide range of materials in industries like minerals, chemicals, and food. Leading industrial dryer manufacturers, such as Economy Solutions, provide customized rotary dryers tailored to specific process requirements, ensuring durability, energy efficiency, and high throughput, making them a preferred choice for industrial drying applications.

ReplyDeleteNeat

ReplyDeleteThank you for the helpful blog, "Sizing Of A Rotary Dryer." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes

Our posts never fail to inspire. You have such a powerful way of sharing knowledge. Hammer Grinder

ReplyDelete