Cooling Tower Design Calculations - Height of Packing & Air Flow Rate

Problem Statement & Given Data:

Warm water at 45°C is to be cooled to 30°C by countercurrent contact

with air in a tower packed with wood slats. The inlet air has a dry-bulb

temperature of 31°C and a wet-bulb temperature of 22°C. The mass flow rate of

water is 6000 kg/m2.h and that of air is 1.4 times the minimum. The

individual gas-phase mass transfer coefficient is kY’a = 6000 kg/m3.h.∆Y’.

The volumetric water-side heat transfer coefficient is given by hLa

= 0.059 x L0.51 x GS, in kcal/m3.h.K,

where L and GS are mass low rates of water and air (dry basis).

Determine (a) the dry air flow rate to be used, (b) the height of packing.

Solution:

(a) Inlet air: TG = 31°C; TW = 22°C = Tas

Humidity

(from Psychrometric chart), Y’1

= 0.01295.

Enthalpy, H’ = [2500 x Y’1

+ (1.005 + 1.88 x Y’1)] x (31 – 0) = 64.3 kg/kg dry air.

Exit water temperature, TL1 = 30°C

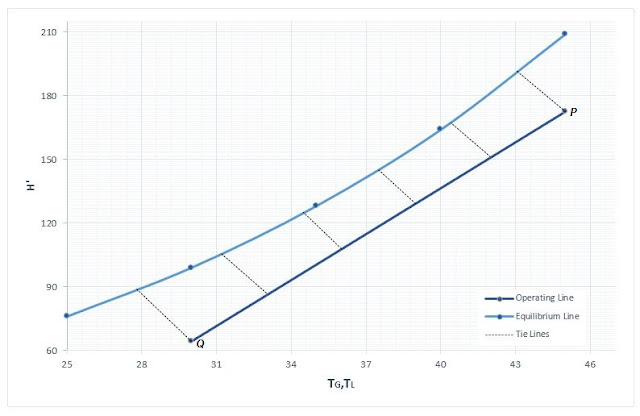

Draw the saturation curve (the equilibrium line) from the calculated

values of saturation enthalpies at different temperatures as shown in Figure 1.

For example, take TL = 35°C (= 308 K). Vapor pressure of water at

this temperature, Pv =

0.05521 bar, and

Y’

= [(0.05521/(1.013 – 0.05521)] x (18.02/28.97) = 0.02 kg moisture/kg dry air

Enthalpy

of saturated air at 35°C [ref. temp = 0°C]

|

| Figure 1 |

|

| Table 1 Equilibrium line data |

Locate the point Q (30°C; 64.3 kJ/kg) on the TL – H’ plane (Q

is the lower terminal of the operating line). In order to determine the minimum

air rate, draw the tangent to the equilibrium curve from the point Q shown in

Figure 1.

Slope

of the tangent = 10.76 = L CWL / GS,min

CWL

= 4.187 kJ/kg.K

L

= 6000 kg/m2.h

GS,min

= 2335 kg/m2.h

Actural

air rate to be used,

GS

= 1.4 x GS,min = 1.4 x 2335

GS = 3270 kg/m2.h (dry basis)

(b) Given, feed water

temperature, TL2 = 45°C. Determine H’2 (enthalpy of the

exit air stream) from the equation of the operating line given below.

L x CWL x (TL2 – TL1)

= G x (H’2 – H’1) = 6000 x 4.187 x (45 – 30) = 3270 x (H’2

– 64.3)

H’2 = 179.6 kJ/kg

Locate the point P (45°C, 179.6 kJ/kg) which is upper terminal of the operating line.

Join PQ.

Calculate the liquid phase heat transfer

coefficient from the given correlation.

hLa

= 0.059 x L0.51 x GS = 0.059 x (6000)0.51

x 3270

= 16,300 kcal/h.m3.°C = 68,260 kJ/h.m3.°C

Slope of the ‘tie lines’ = - hLa/kY’a

= -68,260/6000 = -11.4

A set of tie lines of this

slope (-11.4) is drawn from several points on the operating line (including the

terminal points) as shown in Figure 2. Any such line meets the equilibrium line

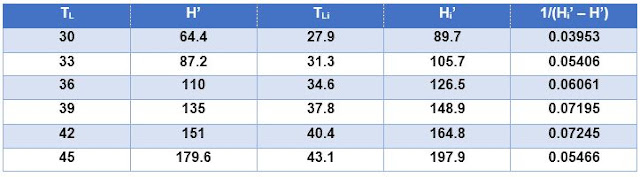

at (TLi, H’i). The set of points (H’, H’i)

thus obtained are given below in Table 2. The values of 1/(H’i – H’) are

plotted against H’ (Figure 3) and the integral in Eq.1 is evaluated numerically.

|

| Equation 1 |

|

| Figure 2 Equilibrium and operating lines |

|

| Table 2 |

|

| Figure 3 |

Use Trapezoidal Rule or any other numerical integration technique to determine NtG ,

Area under

the curve = 7.004 = NtG = number of gas-phase transfer units

Height of

transfer unit, HtG = GS/kY’a = 3270/6000 =

0.545

Packed

height, Z = NtG x HtG

= 7.004 x 0.545 = 3.82 m

Z = 3.82 m

Offering the efficient solutions to the consumers with trust worthy policies, we don’t compromise on qualityiqf freezer manufacturers in chennai

ReplyDeleteThanks for sharing the information.

ReplyDeleteCrystallizer

Hi we are finned tube manufacturer. The Finned Tube regularly used in air cooler and other heat transfer equipment, our website www.lordfintube.com

ReplyDeleteSimulating activities digitally is a useful way to get learners to develop new skills. Doing the real thing is, of course the most important learning experience, but what if the real thing is expensive, dangerous, or deals with the lives of real people?

ReplyDeleteSimulation

san diego water treatment, Really I enjoy your site with effective and useful information. It is included very nice post with a lot of our resources.thanks for share. i enjoy this post.

ReplyDeletechiller rentals, Pretty good post. I just stumbled upon your blog and wanted to say that I have really enjoyed reading your blog posts. Any way I'll be subscribing to your feed and I hope you post again soon. Big thanks for the useful info.

ReplyDeleteIf you are looking for hassle-free maintenance of Packaged type sewage Treatment plant then, you should read this post. After reading this post I got the ideal place for my packaged type sewage Treatment plant maintenance at Clear Ion Expert.

ReplyDeleteHere we come up with new machinery plant named Alaquainc, which specializes in designing and manufacturing a broad range of different crystallizer systems designs to fulfill diverse client requirements. To learn more about Alaqua Inc please visit on the website www.alaquainc.com

ReplyDeleteNice post.

ReplyDeletePortable Air Cooler in Indore

Exercice 1 Détermination de certaines propriétés psychrométriques de l'air-eau insaturé Vapur Mixtur Withour the Psychrometrie Chart: La température sèche-bultb d'un échantillon insituré de sir est de 30 ° C et son pourcentage de saturution est de 50% à une pression de 1013 kN / m. Sans utiliser le diagramme d'humidité, calculez les propriétés suivantes de l'échantillon d'air: (i) Humidité (ii) Saturation relative (ii) Volume humide. Les données de pression de vapeur (ps) pour l'eau sont les suivantes: T. ° C: 6,7 17,2 23,8 28,6 32,6 35,9 38,7 41,2 ps, kN / m2: 0,98 1,96 2,94 3,92 4,90 5,88 6,86 7,85

ReplyDeleteGetting a Landlord Gas Safety Certificate in Hammersmith is mandatory. Here, keeping updated knowledge about the certificate is also necessary and every landlord must do it without any hesitation or delay.

ReplyDelete

ReplyDeleteSarah Cooling is an prominent Plastic Cooler Manufacturers in India. We make use high quality raw material and modern techniques, so as to manufacture products in flexibility with the standards of international market. The doors frames offered by us are made available in varied designs and colours as per the favourites of the clients install. We are provide Air Cooling Pad , Evaporative Cooling Pad, Cellulose Pad provide you the best quality at the best price.

Thank you for sharing this.

ReplyDeleteIn chemical engineering, Process Design Engineering Course is the design of processes for desired physical and/or chemical transformation of materials.

Wow, amazing block structure! How long

ReplyDeleteHave you written a blog before? Working on a blog seems easy.

GiliSoft Video Editor Pro

DefRock Sounds – FUTURE RAVE

Tower Numerics tnxTower

The overview of your website is pretty good, not to mention what it does.

Thanks for great article. One suggestion for removing a small error.

ReplyDeleteCalculation of saturated air at 35 deg C shows humidity 0.02 which should be 0.036. Also bracket closure is wrong giving impression that all terms are multiplied by temp 35 deg C. In fact only terms in second bracket should be multiplied.

Thanks and regard

This comment has been removed by the author.

ReplyDeleteThis blog helps us to explore some new innovation thanks for creating this Best software development company in Chennai

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteNice articles and your information valuable and good articles thank for the sharing information COOLING-TOWER

ReplyDeleteThis was a fantastic read! The focus on sustainability is encouraging. It’s high time the chemical industry embraced long-term ecological responsibility. Santosh Pigment & Chemical Industries Pvt Ltd ! I’d love to see examples of companies that are already making real progress toward net-zero emissions."

ReplyDeleteThank you for the helpful blog, "Cooling Tower Design Calculations - Height of Packing & Air Flow Rate." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes

Thank you for the helpful blog, "Cooling Tower Design Calculations - Height of Packing & Air Flow Rate." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes