Design Calculation (Sizing) Of A Crystallizer

Problem Statement And Given Data:

Given

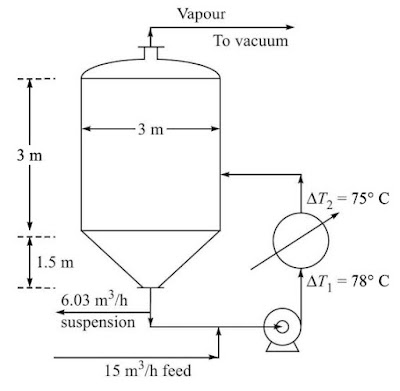

the following data and information, it is required to design a forced

circulation crystallizer of the type shown in Figure 1 operating under vacuum.

|

| Figure 1 Forced circulation (FC) evaporation crystallizer. |

Feed

(an aqueous solution) rate, Qi = 15 m3/h, feed concentration, Ci =

200 kg/m3 solution; feed temperature = 55oC; average

density of the solution = 1100 kg/m3 and average specific heat =

0.90 kcal/kg.oC; operating pressure = 100 mm Hg (660 mm Hg vacuum);

boiling point elevation of the saturated solution = 13oC;

saturation concentration at the crystallization temperature = 250 kg/m3;

magma density allowed, MT = 350 kg crystal/m3 solution;

crystal growth rate determined experimentally under the conditions of the

crystallizer, G = 4.67 x 10-8 m/s; crystal density = 1700 kg/m3;

desired dominant crystal size LD = 0.8 mm; heat of vaporization of

water at the temperature of the crystallizer = 570 kcal/kg; superheat allowed

in the heat exchanger = 3oC; overall heat transfer coefficient in

the heat exchanger U = 1000 kcal/m2.h.oC; low pressure

steam is available for the heat exchanger at 3 kg/cm2 gauge, latent

heat of condensation = 510 kcal/kg.

Solution:

Material balance (basis 1 hour operation)

Solution in = 15 m3 ; solute in = (15 m3)(200 kg/m3) =

3000 kg

Water

in = (15)(1100 - 200) = 13500 kg

Magma

density = 350 kg per cubic meter solution

= 350 kg crystal per

250 kg solute in the solution.

Crystals

produced = [(350)/(350 + 250)] x 3000 kg = 1750 kg.

Solute leaving with mother liquor = 3000 kg - 1750 kg = 1250 kg.

Volume

of solution (clear mother liquor) leaving = 1250 kg / (250 kg/m3,

solubility) = 5 m3

Mass

of solvent (water) leaving = (5 m3)(1100 - 250) kg/m3 =

4250 kg

Mass

of water evaporated = water in with feed – water out with mother liquor

= 13500 – 4250

= 9250 kg

Volume

of slurry leaving per hour = volume of solution + volume of crystals leaving

= 5 m3 + [1750 kg/ (1700 kg/m3)] = 6.03 m3

per hour

Crystallizer Volume

Dominant

size of the product, LD = 0.8 mm = 3GTH ; G = 4.67 x 10-8

m/s (given).

Required

holding time, TH = LD/3G = (8 x 10-4

m)/(3)(4.67 x 10-8 m/s) = 5710 s = 1.6 h

Volume

of suspension in the crystallizer at any time = (6.03 m3/h)(1.6 h) =

9.65 m3

This

is the “working volume” of the crystallizer (note that the suspension holdup in

the pipe line and in the heat exchanger tubes has been neglected). Add 60% to

account for vapour bubbles and froth.

Effective suspension volume in the

crystallizer = (9.65 m3)(1.6) = 15.44 m3

Select

a 3 m diameter vessel (this is to be

checked and changed if necessary) with a conical bottom. Take a cone angle of

45 degrees for the conical bottom.

Volume

of the conical part (radius = depth = 1.5 m) of the tank = (π/3)(1.5)2(1.5)

= 3.53 m3

Volume

of the cylindrical part = 15.44 – 3.53 = 11.91 m3 ; height =

11.91/(π)(1.5)2 = 1.68 m

Add

1.25 m space above the boiling liquid for disengagement of the entrained

droplets.

Total

length of the cylindrical part of the tank = 1.68 m + 1.25 m = 2.93 m say 3 m

Now

check the assumed diameter of the tank.

Absolute

pressure in the vapour space = 760 – 660 = 100 mm Hg = 0.1316 atm

B.P

of water = 52oC. B.P elevation = 130C = B.P of the

solution = 52 + 13 = 65oC = 338 k.

Density

of vapour (steam) at this temperature and pressure, ρv = (18)(0.1316)/(0.0821)(338)

= 0.0854 kg/m3

Volumetric

rate of vapour generation = (9250 kg/h)/(0.0854 kg/m3) =

A

Souders-Brown type equation (Equation 1) is used to determine the allowable velocity

of the vapour without risking entrainment.

|

| Equation 1 |

For

evaporation under vacuum with a demister, a conservative value of Cv

= 0.04 m/s is used.

Allowable

velocity, uv = 0.04 [(1100

/ 0.0854)0.5 ] = 4.54 m/s

Area

required for evaporation = (1.083 x 105 m3/h)/(3600)(4.54 m/s) = 6.63

m2

Cross-section

of the tank = 7.07 m2. Hence a tank of 3 m diameter is suitable.

Energy balance and heat exchanger area

The

feed liquor enters at 55oC; feed rate = 15 m3/h =

(15)/(1100 kg/m3) = 1.65 x 104 kg/h

Take

the B.P of the liquor, 65oC, as the reference temperature.

Required

heat input to raise the liquor temperature to 65oC,

= (1.65 x 104)(0.9)(65

- 55) = 148,500 kcal

Heat

required for evaporation of water = (9250 kg/h)(510 kcal/kg) = 5.272 x 106

kcal/h

(Superheat

of the vapour produced is neglected)

Heat

of crystallization = (1750 kg/h)(30 kcal/kg) = 5.25 x 104 kcal/h

(absorption)

Total

heat input required, Qh = 1.485 x 105 + 5.272 x 106 + 5.25

x 104 = 5.473 x 106 kcal/h

Heating

steam supplied at 3 kg/cm2 gauge (saturated) = steam temperature =

143 oC

Latent

heat = 510 kcal/kg = steam rate = (5.473 x 106 kcal/h)/(510

kcal/kg) = 10,730 kg/h

Heat exchanger area

Temperature

driving force, ∆T1 = 143 – 65 = 78oC; ∆T2 = 143 – 68 = 75oC;

(∆T)m = 76.5oC

Area

of the heat exchanger = Qh/U.(∆T)m = (5.473 x 106)/(1000)(76.5)

= 71.5 m2

An

outline design of the crystallizer is given in Fig 2 below.

|

| Figure 2 An outline diagram of the crystallizer. |

Read crystallizer selection and design considerations articles for better understanding.

I was trying to understand this concept for so long but was unable to understand it. Thanks for sharing this blog it cleared my concepts.

ReplyDeleteCrystallizers supplier in USA

Alaquainc, which specializes in designing and manufacturing a broad range of different crystallizer systems designs to fulfill diverse client requirements.

ReplyDeleteThe process of crystallization is divided into two stages that are primary nucleation and secondary nucleation where primary nucleation helps in the growth of new crystals and secondary nucleation is the main stage of crystal growth that ultimately leads to the crystals’ mass production.

ReplyDeletecrystallizer

crystallizer supplier in usa

crystallizers made in usa

crystallizers supplier

crystallizers supplier in usa

Thanks for sharing. Really helps lot.

ReplyDeleteevaporator system

An evaporator is a processing machine/device used to convert liquid chemicals such as water into vapors or gaseous forms. The evaporator is a chemical processing machine used by various industries for different types of chemical processing.

ReplyDeleterising film evaporators

falling film evaporators

industrial distillation equipment

distillation supplier

This comment has been removed by the author.

ReplyDeleteThank you for the helpful blog, "Design Calculation (Sizing) Of A Crystallizer." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes

I always learn something valuable from your updates. Your perspective is truly refreshing. Groundnut Shell Grinder

ReplyDelete