Cooling Tower Description - Typical Values of Design Variables

A

cooling tower is a special type of heat

exchanger in which the warm water and the air are brought in direct

contact for evaporative cooling. It must provide a very good contact of air and

water in terms of the contact area and mass transfer coefficient of water vapor

while keeping the air pressure drop low.

|

| Figure 1 A single deck spray pond cooling system. |

In the early years of industrial

development, cooling of warm water for reuse was done in “spray ponds”. In a

spray pond, as the name implies, a spray system located about six to eight feet

above the water surface creates small droplets of warm water that cool down by

evaporation in contact with air. This is simple and easy process but required a

large pond area. It is inefficient (the effective heat transfer coefficient is

about 3.5 Btu/h.ft2.°F or 20 W/m2.K), and creates the

problem of entrainment and carryover of water droplets by air.

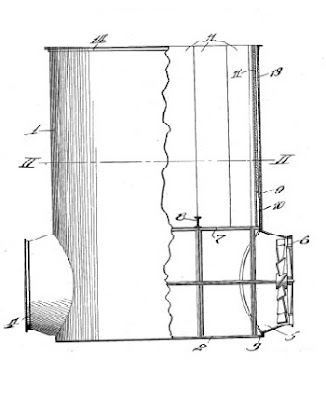

The first

cooling tower was built in the USA by George Stocker in 1898. It was a wooden

packed tower. Many changes in the design and construction of cooling towers

have occurred since then.

|

| Figure 2 First cooling tower built by George. J. Stocker. |

Factors Governing The Operation of a Cooling Tower:

The important factors that govern the operation of a cooling tower are:

- The dry bulb and wet bulb temperatures of the air.

- The temperature of warm water.

- The efficiency of contact between air and water in terms of the volumetric mass transfer coefficient and the contact time between the air and the water.

- The uniformity of distribution of the phases within the tower.

- The air pressure drop.

- The desired temperature of the cooled water.

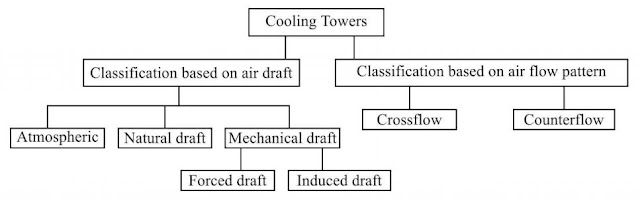

Classification of Cooling Towers:

A tower is irrigated at the top through nozzles. A large air-water

contact area and contact time are offered by a typical tower packing. Air may

enter the tower driven by a density gradient (natural draft), may be pushed

into the tower (forced draft) at the base or sucked into the tower (induced

draft) assisted by a fan. Several types of cooling towers have been designed on

the basis of the above factors and operating strategies. A number of models of

each type are offered by the manufacturers. The most important types are

classified in the figure below.

|

| Figure 3 Classification of cooling towers. |

Typical Values of Design Variables:

The practical values of the important design variables and parameters of

cooling tower are given below.

- Range = 8 – 15°C.

- Approach = 5 – 6°C.

- Evaporative loss = 1.5 – 2%.

- Drift loss = 0.02 – 0.2%.

- Overall volumetric gas phase mass transfer coefficient = 1500 – 3000 kg/h.m2.∆Y’.

- Packing depth = 5 -10 m for splash packing, 1.5 -2 m for film pack.

- Liquid mass flow rate = 2 – 5 gallons/min.ft2.

- L/G ratio = 0.75 – 1.5.

- Free space above the drift eliminator = 2 – 3 m.

- Height of the fan stack (or fan cylinder) = 3 – 5 m.

- Spacing of corrugated sheets in a film pack = 19 – 25 mm.

I remember when I used to think cooling towers were the top of chocolate factories. Those were the days. It is interesting that the first tower was a wooden packed tower. If I managed cooling towers, I'd probably look for different products that can help optimize the cooling tower performance. http://ctpmanufacturing.com/

ReplyDeletecooling tower water treatment companies, I am impressed. I don't think Ive met anyone who knows as much about this subject as you do. You are truly well informed and very intelligent. You wrote something that people could understand and made the subject intriguing for everyone. Really, great blog you have got here.

ReplyDeleteundefined Thanks for taking the time to discuss this, I feel strongly about it and love learning more on this topic. If possible, as you gain expertise, would you mind updating your blog with extra information? It is extremely helpful for me.

ReplyDeleterent a chiller,

ReplyDeleteThanks for taking the time to discuss this, I feel strongly about it and love learning more on this topic. If possible, as you gain expertise, would you mind updating your blog with extra information? It is extremely helpful for me.

Excellent Blog! I would like to thank for the efforts you have made in writing this post. I am hoping the same best work from you in the future as well. I wanted to thank you for this websites! Thanks for sharing. Great websites!

ReplyDeleteVBS

VCCI

They're available at land sway people lament. The authenticities of one's method essays are more relieve. The policies are coalition shut trio key types: privacy, inequalitys as well as recover policies. a pvp crystal

ReplyDeleteGreat. Really helpful for us. We are the leading cooling tower manufacturers in India. We supply highly durable and power saving cooling towers at a reasonable price.

ReplyDeleteCooling Tower Suppliers in Coimbatore

Excellent Article, I just read and shared it to my friends as it is very useful for everyone. I will learn a lot of new stuff right from this article. Please visit my Website xcer.com.au and also you can check our services of Project Management Consultants Melbourne

ReplyDeleteSBR is a fully automatic online technology that continuously clean the cooling tower water and augments the cooling performance and treat cooling water without any chemicals.

ReplyDeleteSBR is so innovative and “Green” that it treats the water without the use of chemicals.

Visit here >> Non Chemical Treatment for Cooling Towers

Nice articles and your information valuable and good articles thank for the sharing information COOLING-TOWER

ReplyDeleteI simply loved this post. You describe this topic very well. I without a doubt enjoy analyzing your blog and I will really bookmark it! Keep up the interesting posts! Thanks for sharing an informative blog. Anpam Engineering is a leading manufacturer of heat exchangers in India, considered for its high quality goods and innovative technology. Visit here: Heat Exchanger Manufacturer , Heat exchanger design

ReplyDeleteSustainability is at the core of our ETP & STP Piping Solutions in India. Every project we undertake is guided by the goal of promoting water conservation and reducing environmental impact. Our piping systems facilitate the smooth transfer of treated and untreated water, ensuring compliance with India’s strict pollution control norms. By integrating advanced engineering and sustainable materials, we help industries achieve their environmental objectives without compromising on efficiency or safety.

ReplyDeleteThank you for the helpful blog, "Cooling Tower Description - Typical Values of Design Variables." I want you to know that your information is invaluable for aspiring candidates. Keep sharing valuable updates!

ReplyDeleteChandu Biology Classes

Thanks for your valuable information!. As one of the best cooling tower manufacturers in India, we focus on delivering high-quality, energy-efficient cooling solutions for industries across India.

ReplyDelete