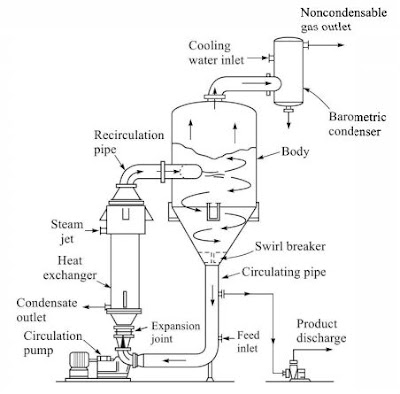

Crystallizer Design Considerations

Crystallizer Design Considerations: Figure 1. Forced circulation evaporative crystallizer . The function of a crystallizer is to produce crystals of a given size specification from a feed are a specific rate. A suitable and adequate supersaturation is created by cooling the feed or by partial evaporation of the solvent. The second method is more common in industrial practice. It has been mentioned before that a narrow particle size distribution of the product is desired to maintain a good product quality. Besides the correct supersaturation and environment (i.e. agitation, pumping rate etc.), techniques like redissolution or classified product removal are helpful to achieve a better product quality. Bath crystallizers require seeding (i.e. addition of fine crystals that act as nuclei). Secondly, nucleation occurs continuously in a continuous crystallizer and seeding is not generally necessary. The more important parameters and quantities involved in the design ...